- About Us

- Pumps

- Industries

We strive to be a fundamental company for society,

contributing globally to contemporary needs and responsibilities. - Service Solutions

We pride ourselves on our proximity, agility, and speed,

and have a deep understanding of the market in Europe and the UK. - Sustainability

- Contact Us

English

Services

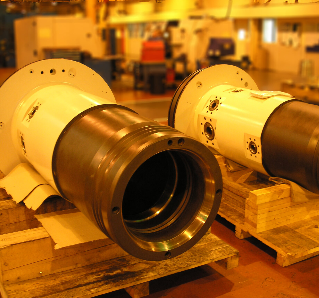

KRG provides a complete aftermarket service covering maintenance, refurbishment, repair and certification of critical assets. We remove, assess and either repair or upgrade components before re machining them to original specification for final testing and return to service.

We manage projects of all scales, from individual spare parts to complex assemblies across multiple sectors. With all machining, welding, testing and inspection capabilities under one roof, we deliver reliable turnaround times that help minimise downtime and keep operations running efficiently.

We offer turnkey manufacturing solutions that cover every stage of production — from material procurement and machining to final inspection.

Using CNC machining and 5-axis capability, we deliver accuracy, consistency and quality for the most demanding applications.

Machine Tool Capability:

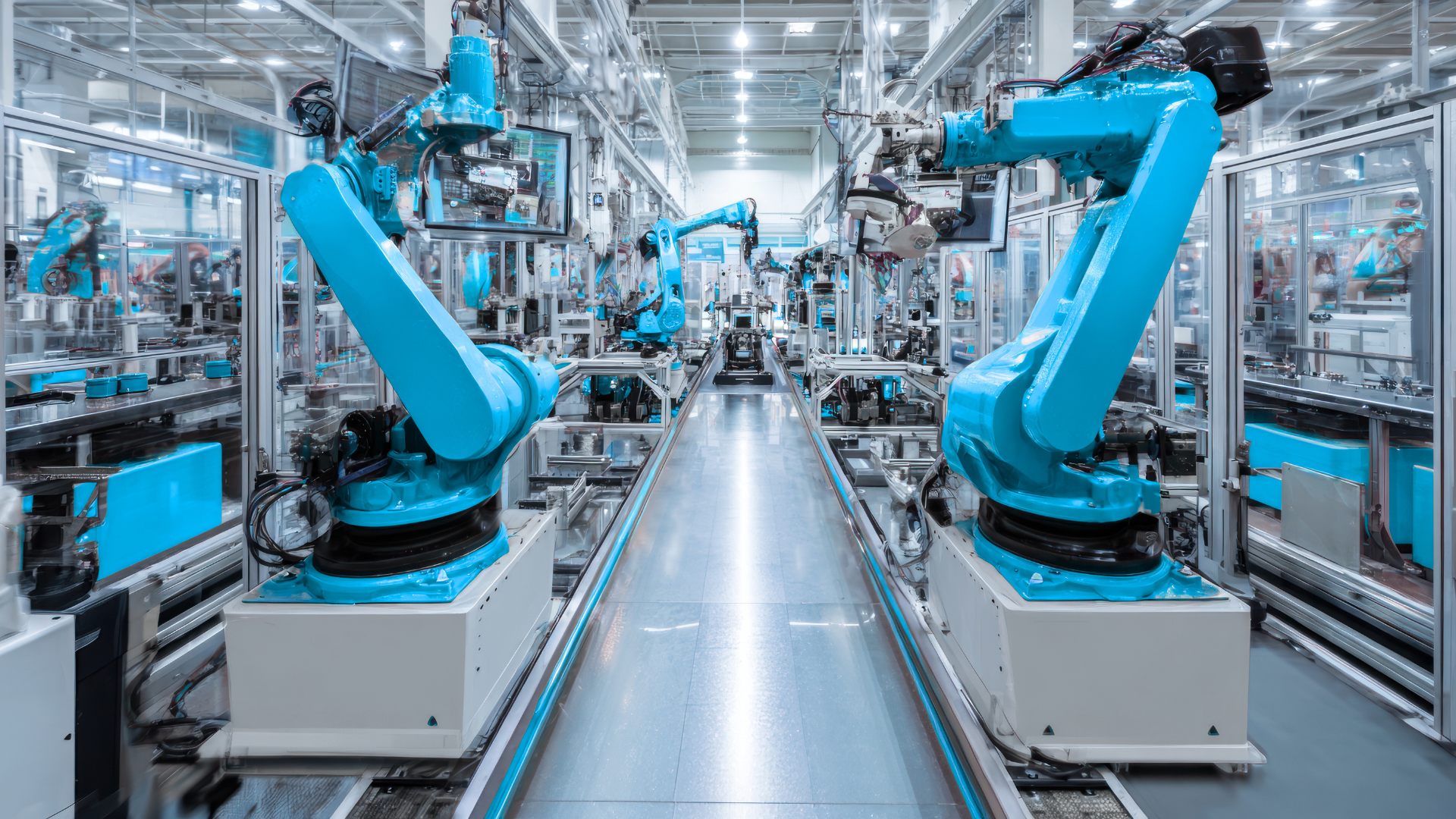

KRG engineer and manufacture special purpose machinery engineered to meet exact customer requirements.

Previous projects include production line machinery for a major food manufacturer, staking rigs for computer chassis, crystal growing machines for fibre optic technology and specialist aluminium extrusion equipment for the cosmetics sector.

KRG provides custom engineered machinery that improves productivity, strengthens process reliability and supports long term operational performance.

KRG provides high integrity non destructive testing to assess the safety, reliability and performance of critical components.

Our PCN Level II inspectors carry out a full range of NDT methods, giving clients the confidence to make informed decisions about asset condition and lifecycle.

Capabilities include:

Our NDT capability supports quality assurance, compliance and operational reliability across demanding industries.

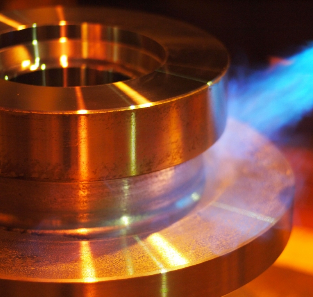

KRG provides high integrity welding and corrosion resistant cladding for both new components and the refurbishment of worn or damaged parts.

Our extensive library of more than 100 certified welding procedure specifications and qualification records enables us to meet the highest quality requirements, including those for high pressure and safety critical systems.

With five Fronius cladding stations, our processes are independently tested and approved to leading international standards including ASME IX, API, NACE, AWS D1.1, ISO 15156, BS EN287/8 and NORSOK.

This ensures consistent performance, structural integrity and long term corrosion protection for demanding applications.

KRG strengthens its quality assurance through advanced coordinate measuring machines and inspection software, enabling precise, repeatable and high capacity measurement for complex components.

Ongoing investment in equipment and processes supports our commitment to operational excellence. Lean, 5S, visual management and KPI driven performance underpin our approach, ensuring consistent efficiency, full compliance and reliable delivery for every project.

Our inspection team includes highly qualified specialists, including CSWIP inspectors, NDT PCN Level II personnel and NACE certified coating applicators and inspectors.

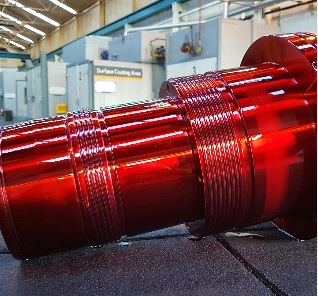

KRG provides a range of high performance surface treatments designed to protect, preserve and extend the life of critical components.

Our dedicated coating facility includes blast rooms, curing ovens, spray booths and controlled storage, allowing us to process both mass production batches and large, high value individual parts.

We apply thin film coatings such as zinc phosphate, Xylan, Molykote and Everslik, along with high build paint systems to NORSOK M 501

Every coating is applied by trained specialists to deliver consistent performance and long term protection in demanding environments.

KRG provides comprehensive testing services to verify the performance, integrity and compliance of client equipment. Testing can be carried out to national, international or industry standards, as well as to enhanced specifications defined by the client.

Assembly is completed in house, and supported by trusted supply chain partners we deliver a wide range of test regimes including hydrostatic, gas and high pressure testing, load testing, site integration testing and factory acceptance testing. This ensures every component or assembly meets the required level of reliability before entering service.