Torishima Pump Mfg. Co., Ltd. (hereinafter “Torishima”) has successfully conducted operational testing of its newly developed commercial-scale ammonia pump using actual liquid ammonia. The test confirmed that the pump delivered the expected performance.

1. Background

In Japan, the adoption of fuel ammonia is steadily progressing as part of the country’s efforts to achieve carbon neutrality by 2050. Ammonia is gaining attention as a next-generation clean fuel because it does not emit CO₂ when combusted. Under the “Green Growth Strategy,” the Japanese government has positioned ammonia alongside hydrogen as a carbon-free fuel, and is promoting the development of fuel ammonia supply infrastructure and co-firing technology for thermal power generation, through public-private partnership.

To fully utilize ammonia as a fuel, large-capacity and high-flow supply systems are necessary. However, due to ammonia’s high toxicity, increased capacity and flow demand even higher safety standards for handling systems.

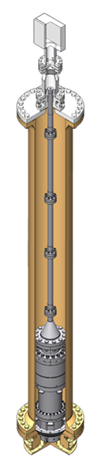

To address this, Torishima has developed a submersible in-tank pump designed to minimize ammonia dispersion not only during operation but also during maintenance. The pump’s development prioritized safety above all. Its structure minimizes the release of ammonia gas from the column pipe opening when the pump is lifted from the storage tank for maintenance. Additionally, drawing from technologies cultivated in its drainage pumps, Torishima has achieved a high suction performance that allows for nearly complete extraction of liquid from the bottom of the storage tank.

2. Test Overview

From January to February 2025, Torishima conducted operational testing using actual liquid ammonia with the newly developed commercial-scale in-tank pump at the factory of P.T. Torishima Guna Engineering, a subsidiary of Torishima in Indonesia..

The results were favorable and consistent with expectations.

The flow rate confirmed during the test corresponds to the discharge capacity required for a 40,000-ton tank, demonstrating that the pump system is suitable for large-scale use of fuel ammonia.

3. Future Outlook

This test successfully demonstrated the performance and safety of the pump system under real-world conditions, proving its suitablility for large-scale fuel ammonia supply.

Moving forward, Torishima will actively promote this technology in both domestic and international fuel ammonia-related projects.

Moreover, by offering flexible solutions tailored to customer needs and on-site conditions, Torishima aims to contribute to the widespread adoption of next-generation clean energy and the realization of a carbon-neutral society.